ELIZABETHTOWN, Ky. (WDRB) — BlueOval SK, the company building three battery plants in Kentucky and Tennessee to supply Ford Motor Co.’s electric vehicles, is “well aware” of complaints about exposure to mold at its Glendale, Ky. construction site and of a related investigation by occupational health and safety officials, its CEO said Thursday.

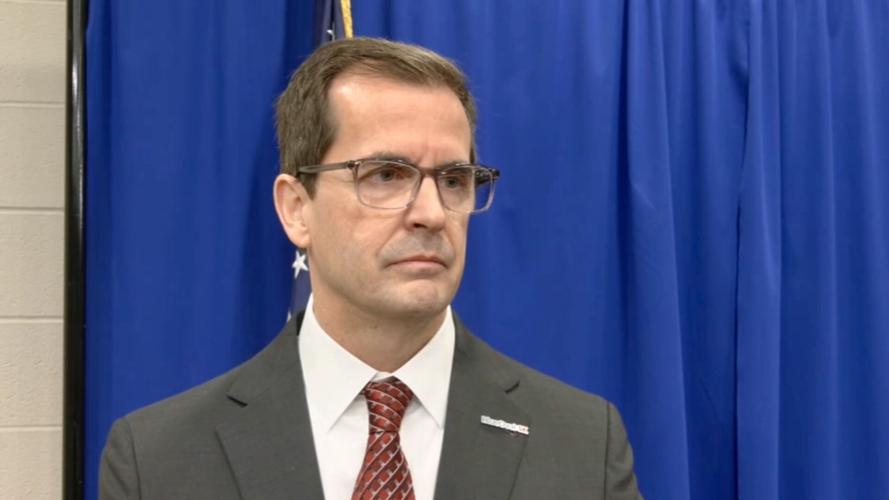

The mold will have “no impact” on the planned start of EV battery production next year at the first of two side-by-side plants at the Kentucky site, said Michael Adams, CEO of BlueOval SK, in an interview.

“We’re well aware of the mold situation. The safety of all the employees on the site — whether they are BlueOval SK employees or other contractors’ employees — is paramount, and everything is being managed,” Adams told WDRB News following an event to announce the company’s $500,000 donation to Family Scholar House’s campus in Elizabethtown, Ky.

Adams reiterated the company’s previous disclosure of an occupational health and safety investigation related to the mold issue and added that it will “have no impact on BlueOval SK employees or the start of production.”

WDRB News first reported earlier this month on widespread complaints among construction workers such as laborers and electricians on the BlueOval SK site about mold on wooden crates containing factory equipment be to installed.

“It’s like if you walked into a crypt or something — just horrible. It will knock you down when you open the crates or containers or even walk in the door on some floors,” James Dugan, an electrician who previously worked for one of the many subcontractors on the project, told WDRB News earlier this month.

WDRB News obtained a 46-page environmental report produced in December for Abel Construction, the Louisville-based contractor responsible for installing equipment at the factory, which confirmed the presence of mold on crates and in tractor trailers, sometimes in high concentrations.

However, an executive with Abel Construction told WDRB News on Feb. 1 that three independent experts confirmed the mold is safe to work around though it may cause “slight irritation” to employees who have preexisting health conditions.

In its previous response, BlueOval SK said construction workers on the project are not its employees and referred questions to the Occupational Health & Safety Administration, the regulatory agency for workplace safety.

Asked on Thursday how the situation is “being managed,” BlueOval SK’s CEO said the company isn’t handling it directly.

“We’re not directly involved in that as the contractors are on site, so I will decline that question,” Adams said.

The Kentucky Labor Cabinet, which administers OSHA matters in the state, declined to comment earlier this month on an active investigation and did not immediately respond when contacted Thursday.

BlueOval SK is a 50-50 partnership between Ford and Korean technology company SK On. Ford has poured about $3 billion into BlueOval SK since it was formed three years ago, according to the company’s latest annual report.

BlueOval SK will produce batteries for Ford and Lincoln EVs and is a lynchpin of the company’s strategy to make profitable electric models while taking advantage of generous federal tax credits for United States production of batteries and their components.

Ford lost $4.7 billion on its EV business in 2023 and projects losing another $5 billion or so in 2024. The company has told analysts to eventually expect 8% profit margins on EVs.

“We know that the EV business needs to stand on its own,” Ford chief financial officer John Lawler said earlier this month.

The Kentucky BlueOval SK factories represent the biggest economic development project, at nearly $6 billion, in state history. However, Ford last year indefinitely paused the start of production at the second Kentucky factory as part of a plan to delay about $12 billion in EV investments.

Automakers such as Ford and GM have paired back their EV ambitions as demand for the vehicles, while still growing, has moderated in the last year. Ford has dialed down production of its F-150 Lightning EV pickups and on Wednesday announced price cuts to its Mustang Mach-E electric SUV.

Louisville has a lot riding on the EV transition, as Ford plans an “all new” electric model at Louisville Assembly Plant in 2026. More than 3,000 hourly workers at the plant currently build the Escape SUV.

The first of the two Kentucky plants will be dedicated to making batteries for Ford’s commercial vehicles such as the E-Transit work van, a Ford executive told WDRB News last year.

WDRB reporter Amanda Roberts contributed to this story.